Culture is what distinguishes humans from other creatures. The mind and intellect drive Humans to constantly seek, acquire and use everything with the purpose of making it better.

PT Avesta Continental Pack’s journey to cultivate Conim has started since five decades ago, starting from the simplest Conim (individual) to even group Conim (Quality Control Circle method).

The principles that make Conim sustainable involve the following :

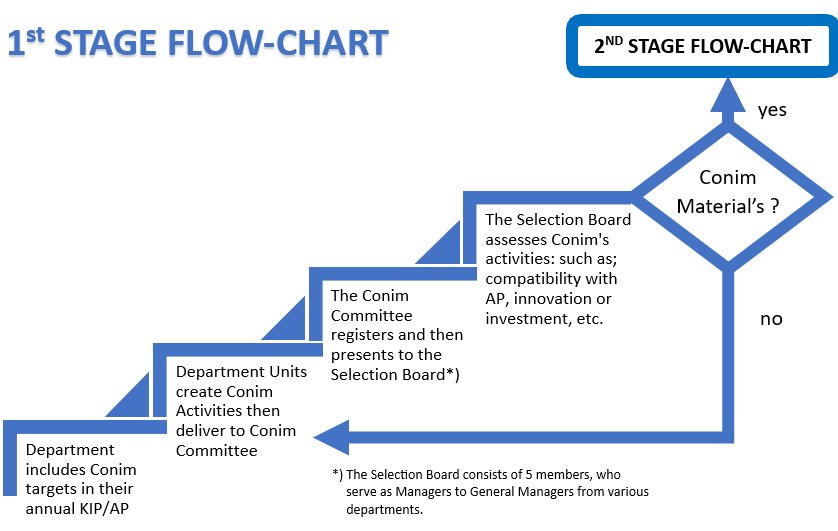

1. Commitment (PLAN)

Commitment is the ‘primary gate’ of Conim implementation, and the ‘key’ of the gate is directed by the top management. Commitment is carried out in each Department level as Conim actors.

2. Learning (DO)

Debriefing should continue to be done as a refresher, to introduce current/new methods and also to equip understanding for rotating or new employees.

3. Implementation (CHECK)

The Conim Committee also manages to establish communication between Department Heads and improvement implementers for certain issues; such as meeting directly on site and discussing together with improvement implementers in the field.

4. Empower (ACTION)

The three stages above will eventually culminate in this stage in accordance with the elaboration of the PDCA concept. After employees get fully supported by management, provision and assistance, it is time to make it happen.

Continuous Improvement is a way of life that must be carried out to be able to face the challenges that are in front of us, as individuals and as an organization. PT Avesta Continental Pack still stands and will continue to exist because it has committed, invested, nurtured and executed to actualize Continuous Improvement for sustainability.