- Home

- About Us

- Product

Our Product

We are the main producer and specialist for flexible packaging in Indonesia.

-

What's NewWhat's New

-

ISO CertificationISO Certification

-

Product StructureProduct Structure

-

PortfolioPortfolio

-

Production ProcessProduction Process

-

Contact UsContact Us

-

Product ShapeProduct Shape

-

Our CustomerOur Customer

-

QC and R&DQC and R&D

-

- News & Gallery

- Contact Us

- Career

Our Product

The result of our high-tech production line is quality flexible packaging products such as laminated aluminium foil, laminated plastic film and coated aluminium foil in roll and pouch forms, in compliance with the high industry standard

We Never Stop Innovating

Continuous innovation is one of our ways to meet customer needs and respond to dynamic market challenges by improving the technology used, developing human resources and others.

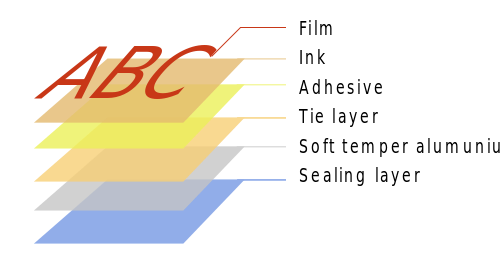

Main Flexible Packaging Product Structure

The development of market needs affects the type of packaging needed according to its designation. This is a challenge for us to answer the market’s needs by preparing packaging with an appropriate structure.

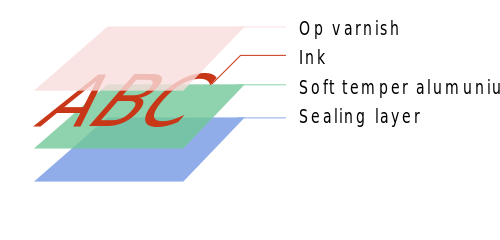

Polycello

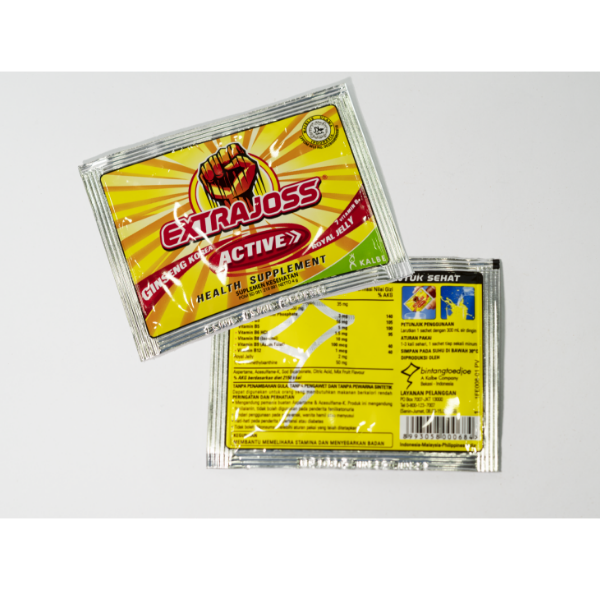

This structure is usually used for products that are stable and the contents are not much affected by direct sunlight, can be used for packaging medicine, food and also products for daily household needs.

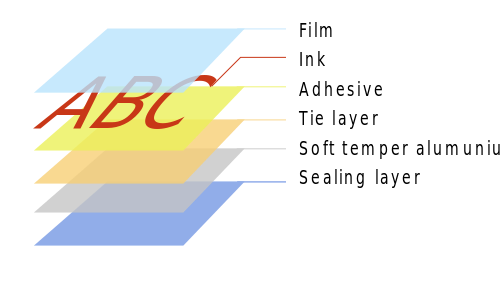

Polycellonium

This product is commonly used for products that require high & strength barrier, such as products containing Effervescent, Aroma and other active substances that are sensitive to the transmission of gas / aroma, water vapor and direct sunlight.

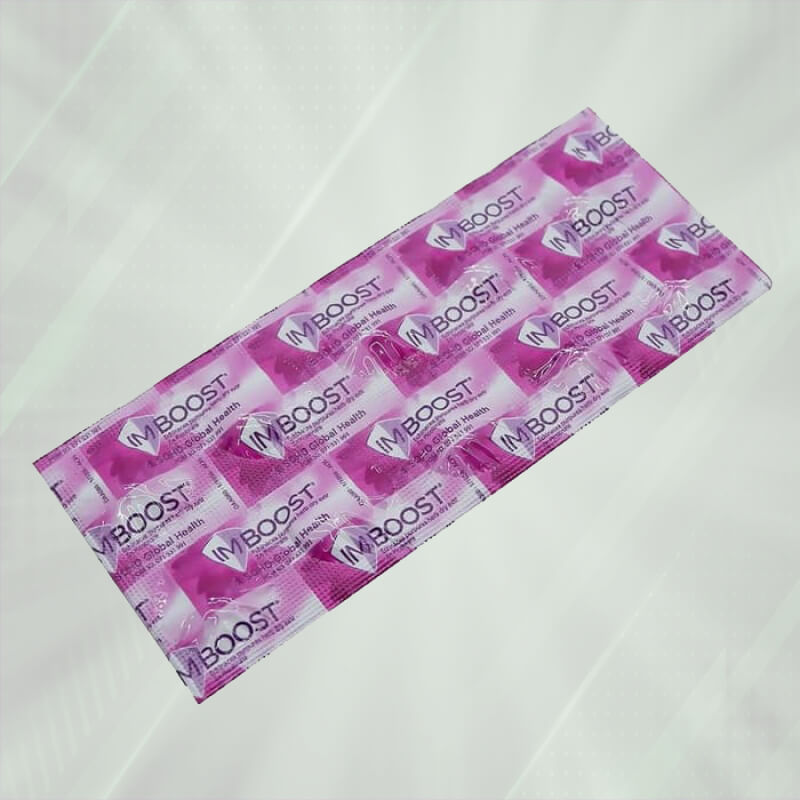

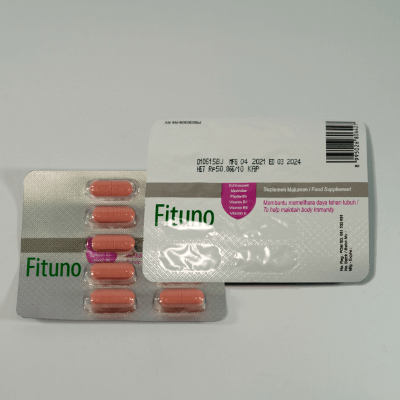

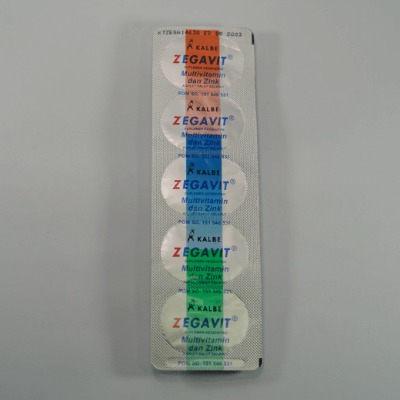

Polynium

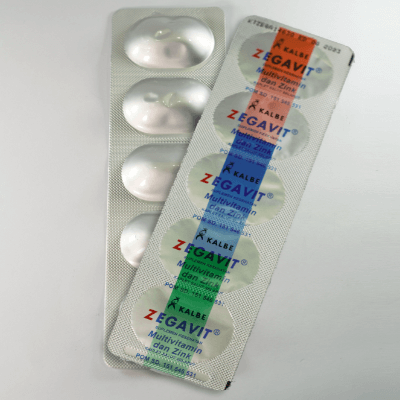

Used for products that require a high barrier to sunlight, gas and water vapor, and require a product filling process at a lower temperature, generally for multivitamin packaging.

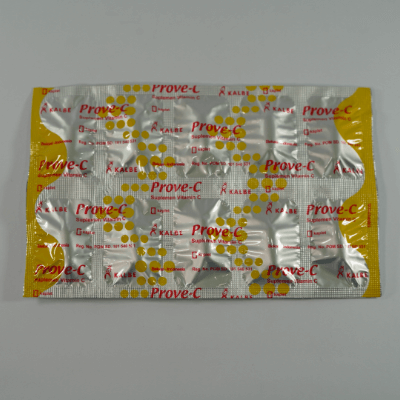

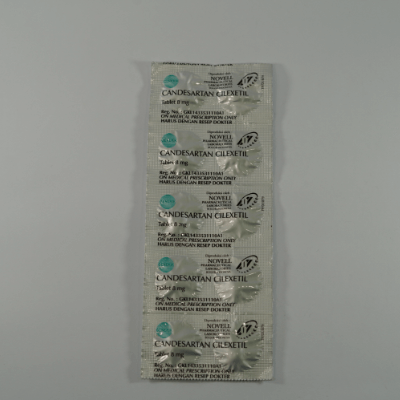

PTP

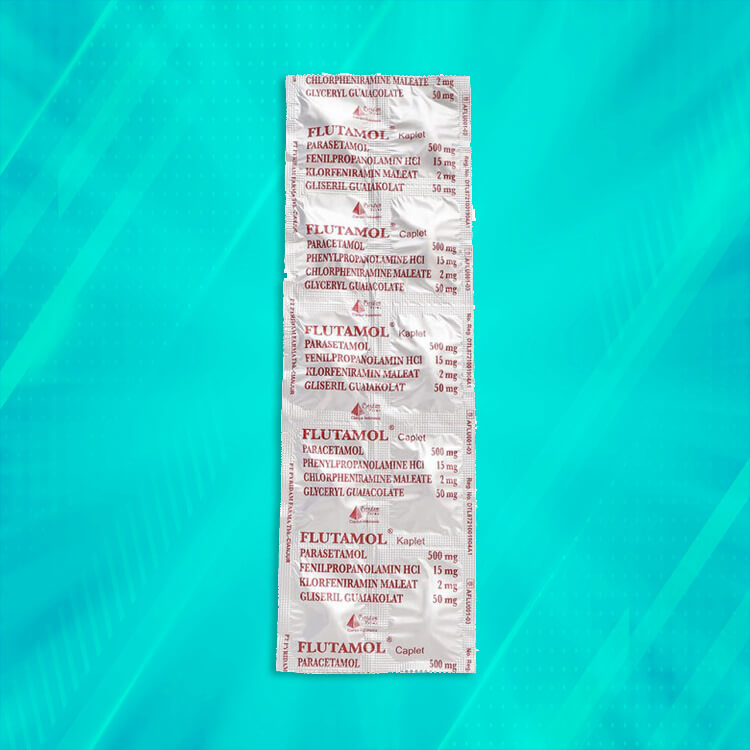

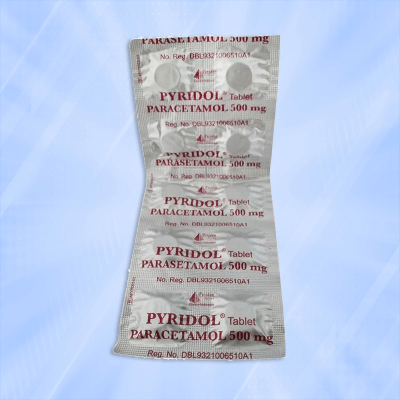

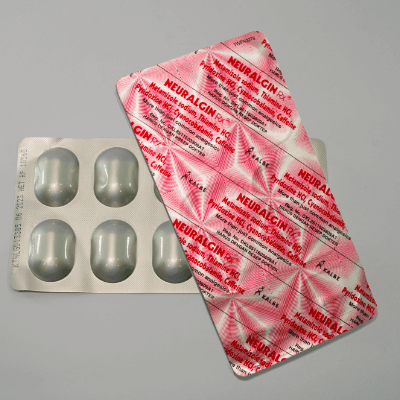

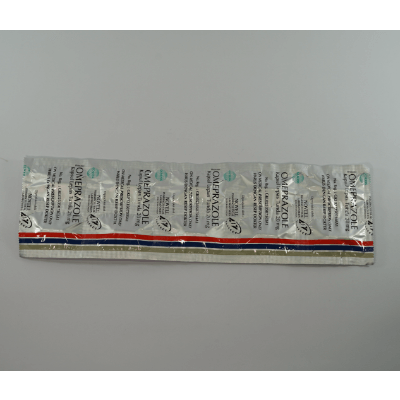

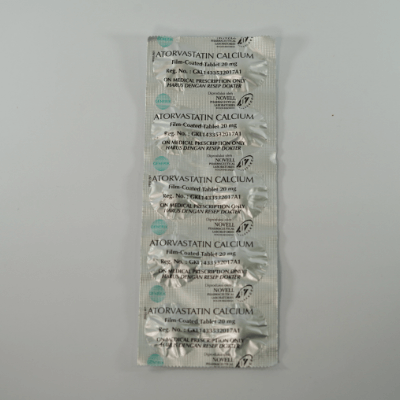

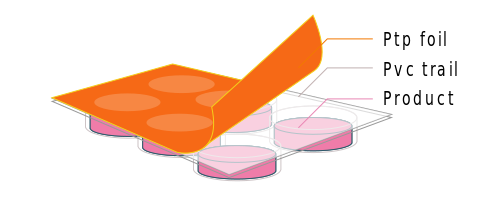

Commonly used for packaging stable products, such as Paracetamol medicine, Ulcer medicine, Diarrhea medicine and Hair tonic.

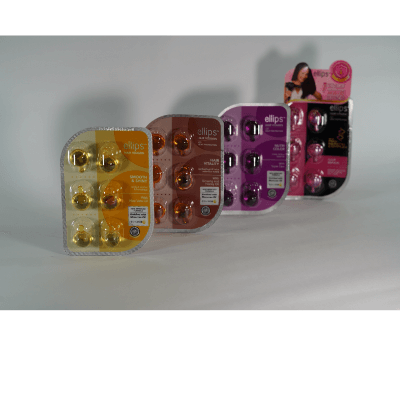

PTP for Blister

Commonly used for packaging stable products, such as Paracetamol medicine, Ulcer medicine, Diarrhea medicine and Hair tonic.

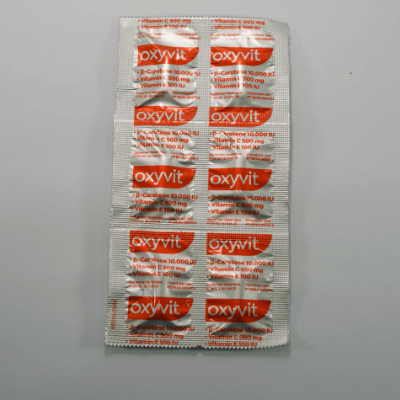

Deep Drawn Tray

Used for packaging multivitamins that need a high barrier to sunlight.

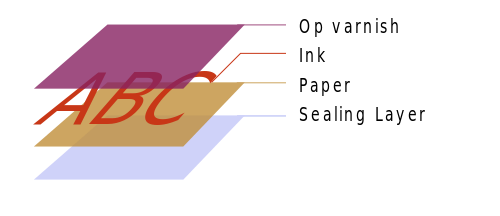

Polypaper 1

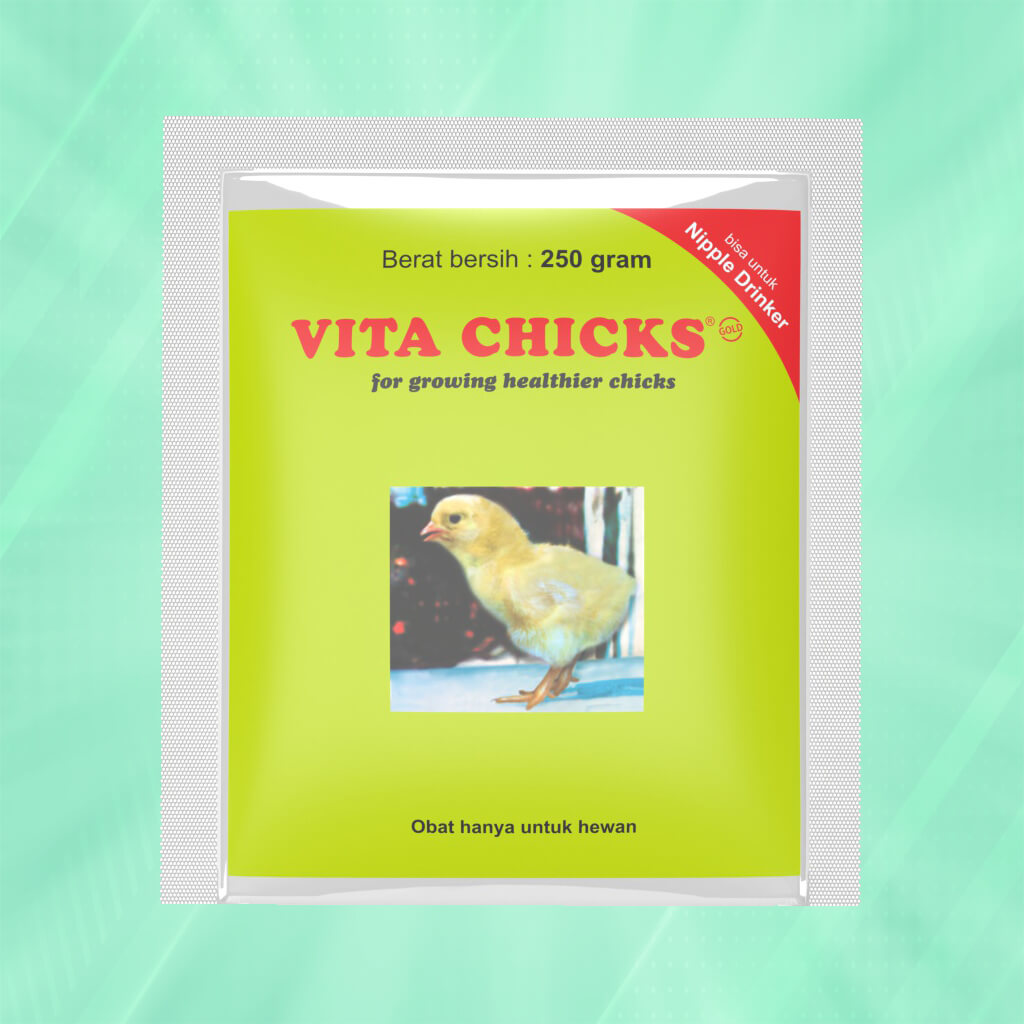

Used for packaging products that do not require a high barrier, such as for packaging sugar or tea for the hospitality industry, silica gel and others.

Polypaper 2

Used for packaging products that do not require a high barrier, such as for packaging sugar or tea for the hospitality industry, silica gel and others.

Polypanium

This structure is commonly used for products that require high rigidity and are easy to form, such as composite cans for oil, food chips and also for packaging such as cones for ice cream.

Production Process

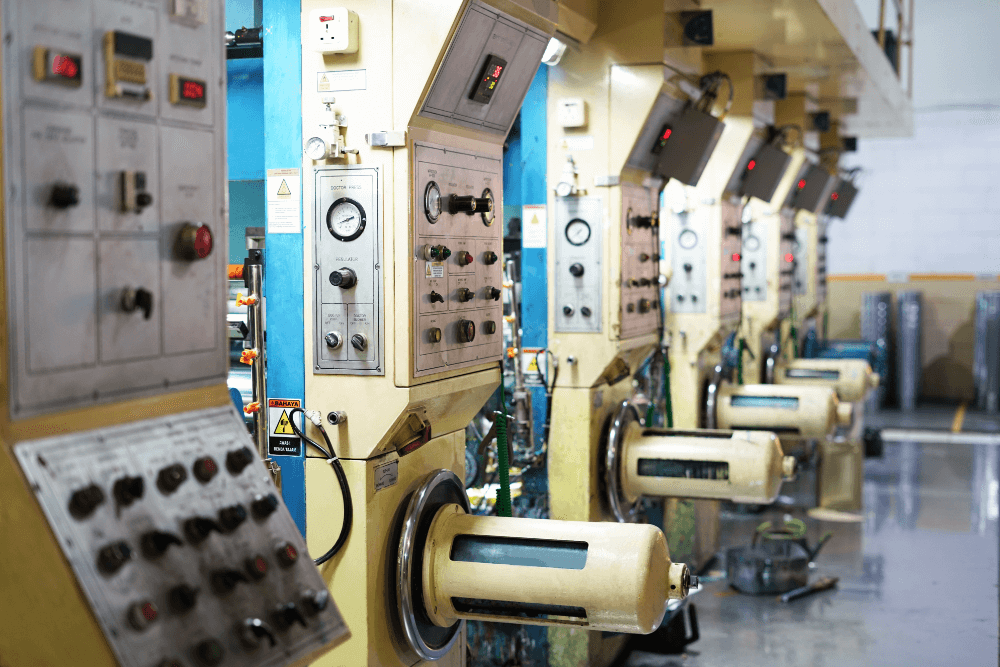

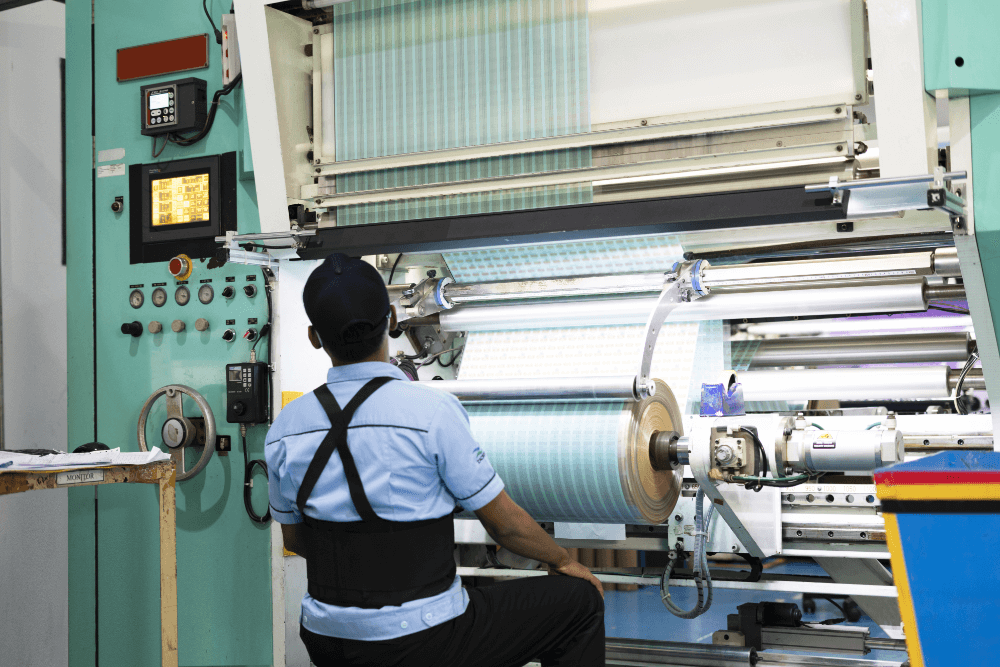

Printing

The printing process uses a rotogravure printing machine with a capacity of up to eight colors in one process. To get accurate printing results, each unit is equipped with automatic register control. In addition, a viscosty controller is used to keep color quality stable.

Each process is supervised by experienced supervisors either through the monitor screen on the printing machine or directly seeing the resulting product.

Production Process

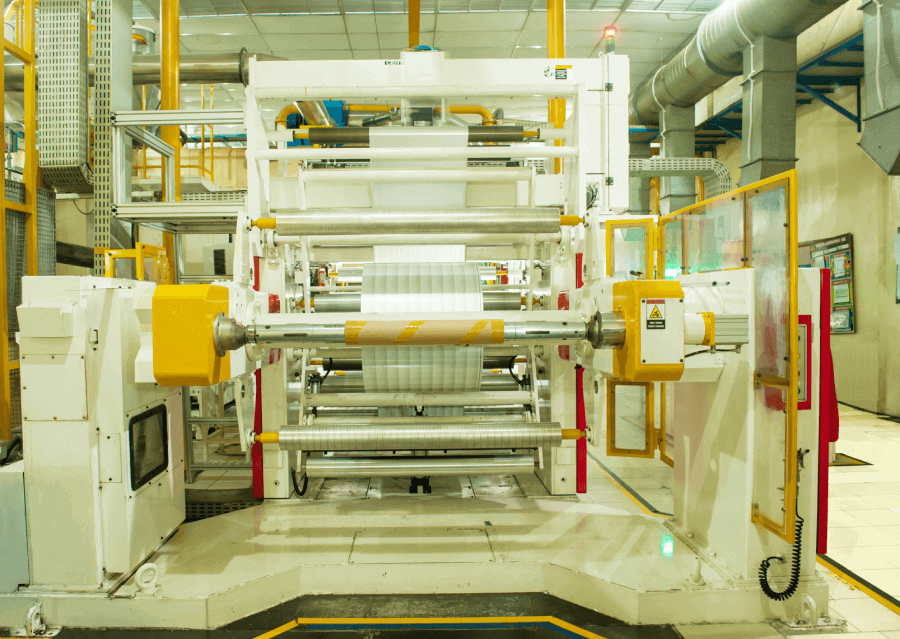

Lamination

Using a dry lamination machine, single extruder and tandem extruder that can produce two layers of polymer in one process, and has been equipped with an automatic thickness control system, with the aim of making the lamination process more efficient.

Production Process

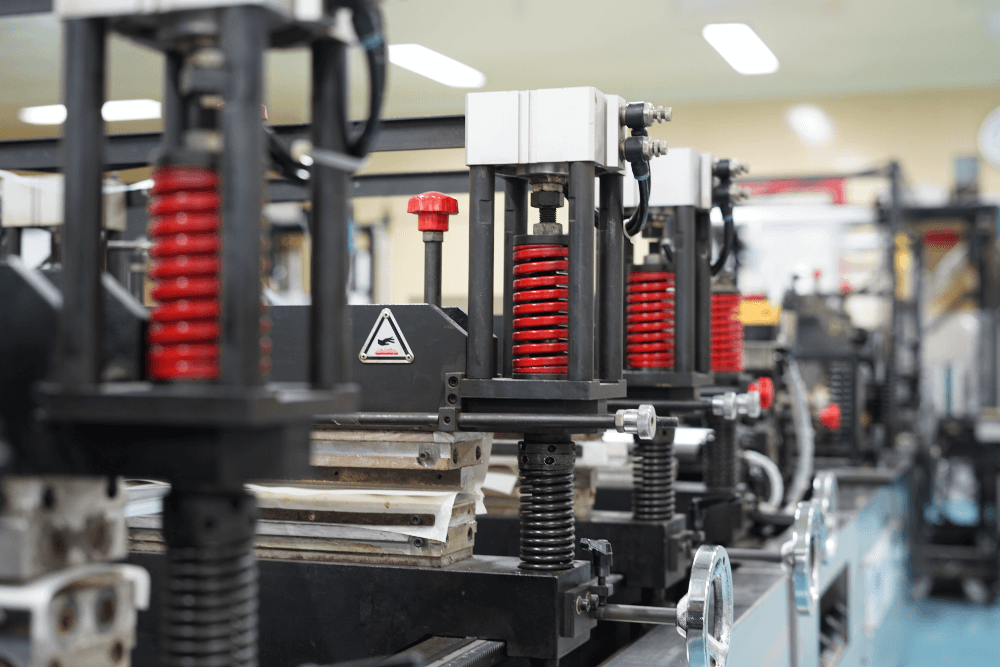

Slitting

Our slitting machine can make adjustment in cutting size from large rolls into various smaller sizes according to Customer’s requirements. Our machines are also equipped with a material tension controller to produce materials with consistent tension.

Production Process

Bag Making

The Bag Making Machine is capable of making bags with a center seal and a side seal on the other, a stand-up bag with a zipper closure. Customers can also order special bags for products that go through the vacuum process and the retort process. We are able to make Bag Making Products such as 3 side seal, Gusset, Center Seal and standing pouch.

Production Process

Inspection

Each proccesed product will be subjected to an inspection process with a rewinding machine equipped with a high-resolution and high-speed camera that can capture defects automatically. Therefore, every product that has been inspected is eligible to proceed to the next process.

Production Process

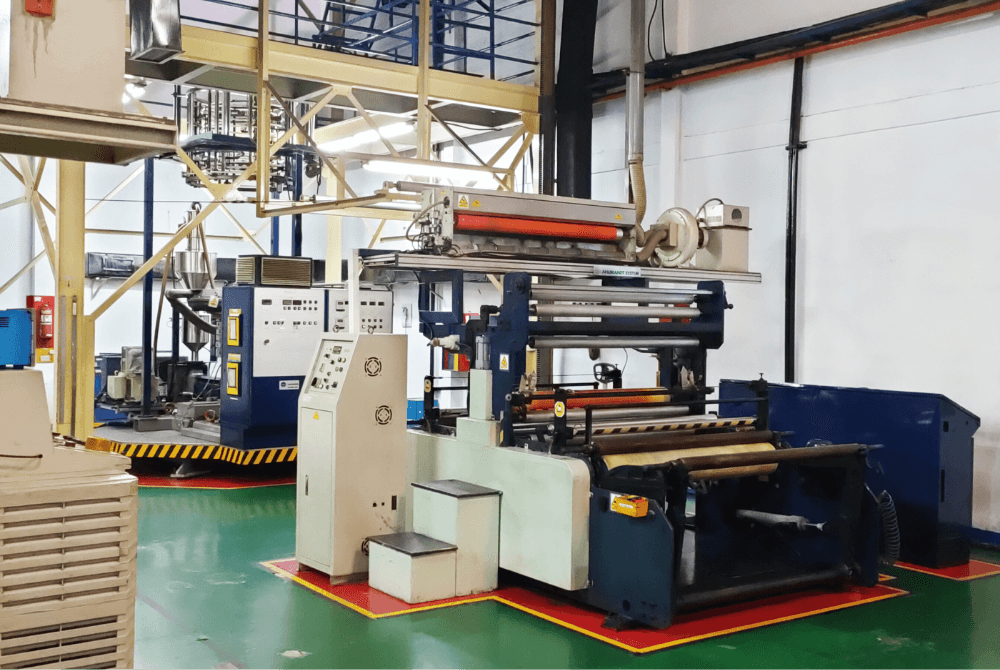

Blown Film

The blown film machine is used for the process of making polymer sheets that will be used for coatings in the dry lamination process.

We have a monolayer blown film machine to produce LLDPE sheets which are used as sealing layers of packaging products. We formulate and produce various types of LLDPE materials according to customer requirements for solid and liquid packaging. We have a reliable research and development team to formulate and manufacture specific LLDPE sheet materials according to customer needs. Having an RnD team and blown film machine in our production line, we can deliver specific packaging orders to customers more quickly.

In the next 2 years we will equip a blown film machine with multi layer blown film to produce LLDPE sheet products that have a larger output in line with market demand growth, and produce higher performance LLDPE sheets to meet the needs of customers whose require product more reliable packaging.

Product Shape

We are constantly following market developments

The rapid development of the market has an influence on the needs that continue to increase. Including the need for the form of packaging of a product that will be the main attraction and a factor supporting the behavior of the product in the market. We as a supplier, actively follow these developments according to customers requirement.

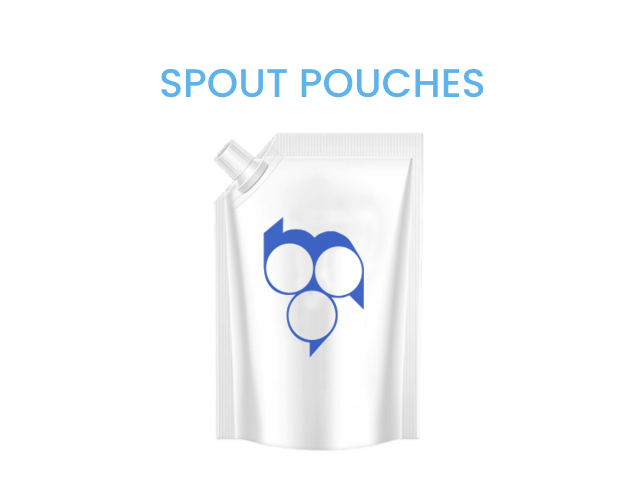

Spout Pouches Product

- More practical in use.

- More attractive appearance.

- Save space and shipping costs.

- Cheaper than using bottle packaging.

- Can be printed on all packaging surfaces with high image resolution

- The shape, type, position and size of the spout can be adjusted to the size of the packaging to be used.

- Using materials that are more efficient than the materials used for making bottles, environmentally friendly, and recyclable.

Standing Pouches / Doypack

- The selling price is more affordable.

- Sizes vary, ranging from 50 grams, 100 grams, 250 grams, 500 grams, 1000 grams to 2 kg.

- The structure of packaging materials in the form of aluminum foil, plastic, kraft paper and laminates of various compositions as needed.

- This type of packaging can also be equipped with a zipper lock to make the packaging easy to open and close. It is more practical and preferred by consumers, because the remaining contents of the packaging are more durable.

- The bottom side has aan oval surface shape. This packaging type can stand upright when placed on a shelf, making it easier for consumers to see the name, brand and product information. This stand pouch packaging model is the most choosen packaging form.

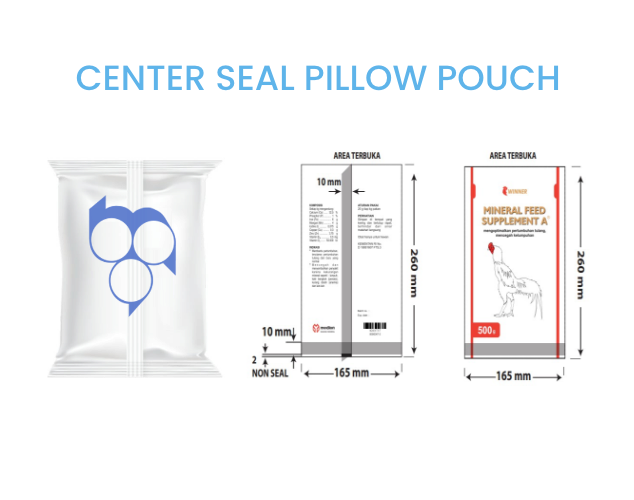

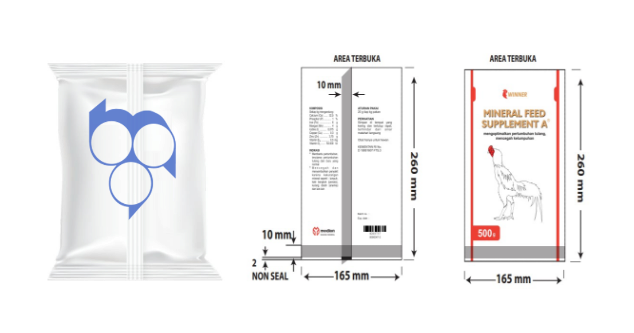

Center Seal Pillow Pouch

- This type of packaging is one of the most economical forms of packaging widely used in the market.

- The structure of the material used can be plastic lamination, metalized lamination, paper lamination and also Aluminum foil lamination.

- Widely used for food packaging that is light in weight and does not require a long service life, such as instant noodles, sugar, coffee, snacks, powdered milk that is included in the box and others.

- The seal is located on the back extending along the entire length of the bag, thus it is referred to as a “Back Seal Pouch or T Seal”. The top or bottom side is usually left open to fill the product. Once filled, it looks like a pillow.

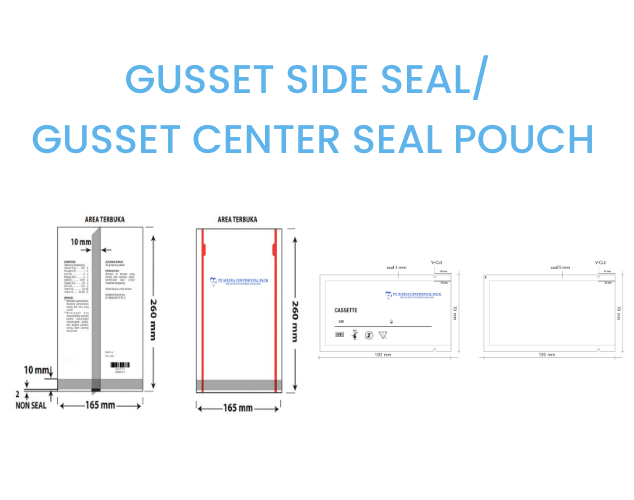

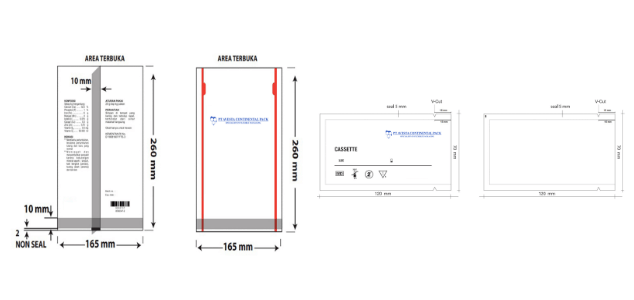

Gusset Side Seal / Gusset Center Seal Pouch

- The structure of Gusset packaging materials varies depending on needs. The structure can be plastic laminate, metalized laminate and can also be aluminum foil laminate.

- Widely used for packaging powdered products such as detergent, milk in boxes and for bean-shaped products such as coffee. Rarely used for products in the form of paste or liquid.

- The gusset packaging is a quite unique and interesting form of packaging because the shape of this product will be in the form of a box that bulges in the middle like a pillow when it is filled. Therefore is called pillow packaging.

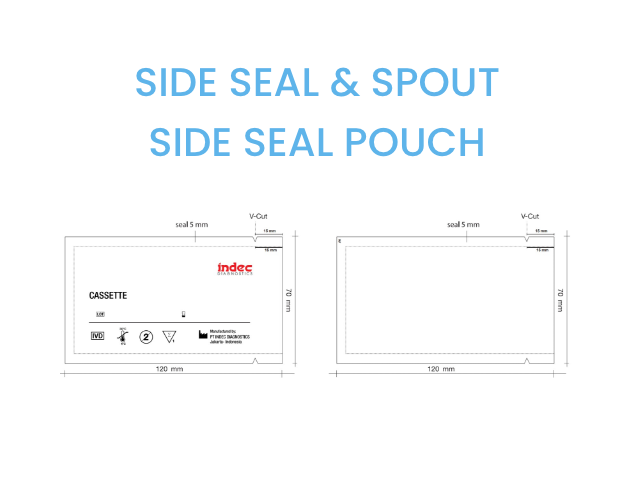

Side Seal & Spout Side Seal Pouch

- The price of sachet products is usually cheaper.

- Concise product concept usually for one time use.

- Sachet packaging can also have additional accessories such as zipper and spout.

- Some travel pack products are very attractive when packaged in sachet sizes, such as shampoo, liquid soap, toothpaste, and make up.

- This type of packaging is practical, mini size, easy to carry anywhere, easy to open, and very light making this type of sachet packaging very popular.

- Products that are included in this compact package can also function as sample products so that consumers can know and get to know the products that are offered first.

- Three side seal bag (Sachet) is a type of packaging that has been sealed on all three sides on the left, right, and bottom. Customers can enter the product through the top side and then seal it and the packaging is tightly closed.

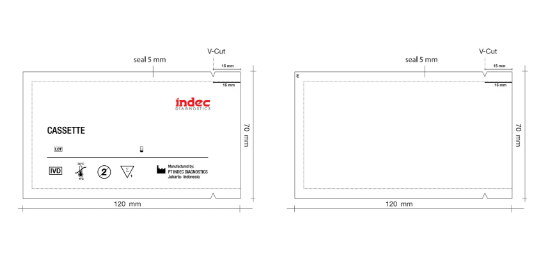

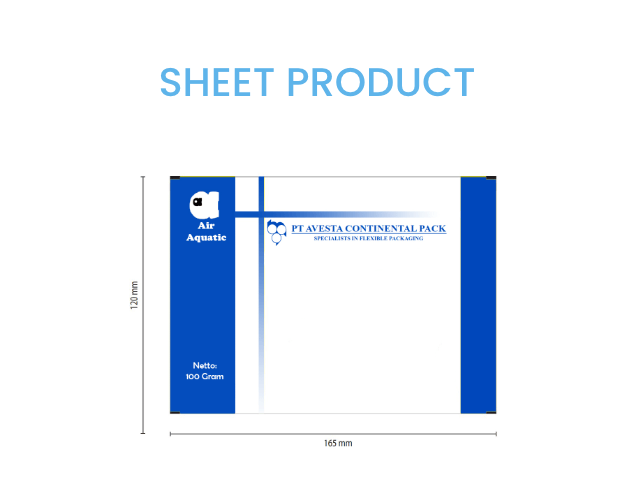

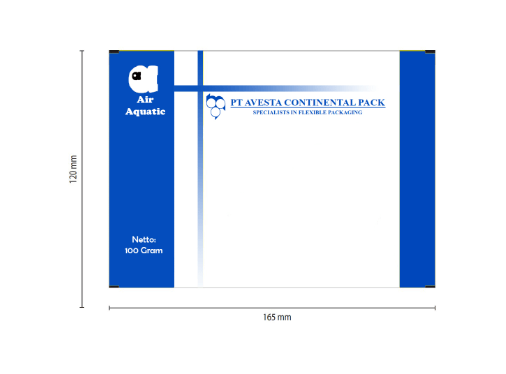

Sheet Product

- The work takes longer because it has to be done sheet by sheet.

- The structure of the materials used are generally Blister (PTP), aluminum lamination, plastic lamination and metalize and paper lamination.

- Product packaging materials for this sheet/sheet model are widely used for lids or tray covers such as frozen worms, also for cup covers/plastic bottle containers such as for scrubs, yogurt and others.

Quality Control

All production must go through the stages of quality control

Quality Control is an important part that cannot be separated in the product manufacturing process, both in terms of design and the production process itself. This is done with the aim of getting the best product according to the Customer needs or specifications.

The Quality Control process that we carry out starts from the arrival of raw materials from suppliers which is useful for providing quality assurance of materials to the production department to proceed to the production process stage. Furthermore, the Quality Control process is also carried out in the production process section to ensure each production process runs according to the standards we have set. Other than that, Quality Control is also carried out after the production process is completed to ensure that all products produced are in accordance with specifications and are suitable for us to deliver on to our customers.

We guarantee that every product we produce has gone through the stages that we have standardized and strict quality checks.

RESEARCH AND DEVELOPMENT DEPARTMENT

We have reliable human resources and the latest technology

The Research and Development Department (R&D) is the part that functions to make formulations in the manufacture of Packaging Products that are made in accordance with the characteristics of the material (content) to be packaged and also in accordance with the specifications on the customer’s machine. In addition, R&D also strives to continue to create environmentally friendly products to be able to adapt to current conditions.

Currently, we have been able to create several featured products such as: Polycellonium, Polycello, Polypaper, Polymetalized, Polynium, PTP Blister, Polypanium and Deepdrawn. Besides in roll form, we are also able to make other pouch products including: 3 Side Seal, Gusset, Center Seal and Standing Pouch.

RnD is our main line to carry out innovations for product development according to customer needs and technological developments both in Indonesia and globally. And we never stop to innovate products which of course is beneficial for customers for the development and innovation of their products.

ISO Certification

Avesta in System implementation ISO 9001 Quality Management

On January 15, 1997, the results of the company’s hard work were proven by obtaining ISO 9001 certification in design and flexible packaging production, which was later upgraded to ISO 9001:2015. Until now, periodic audits by DQS continue to be carried out to confirm our consistency in implementing the ISO 9001 Quality Management System.

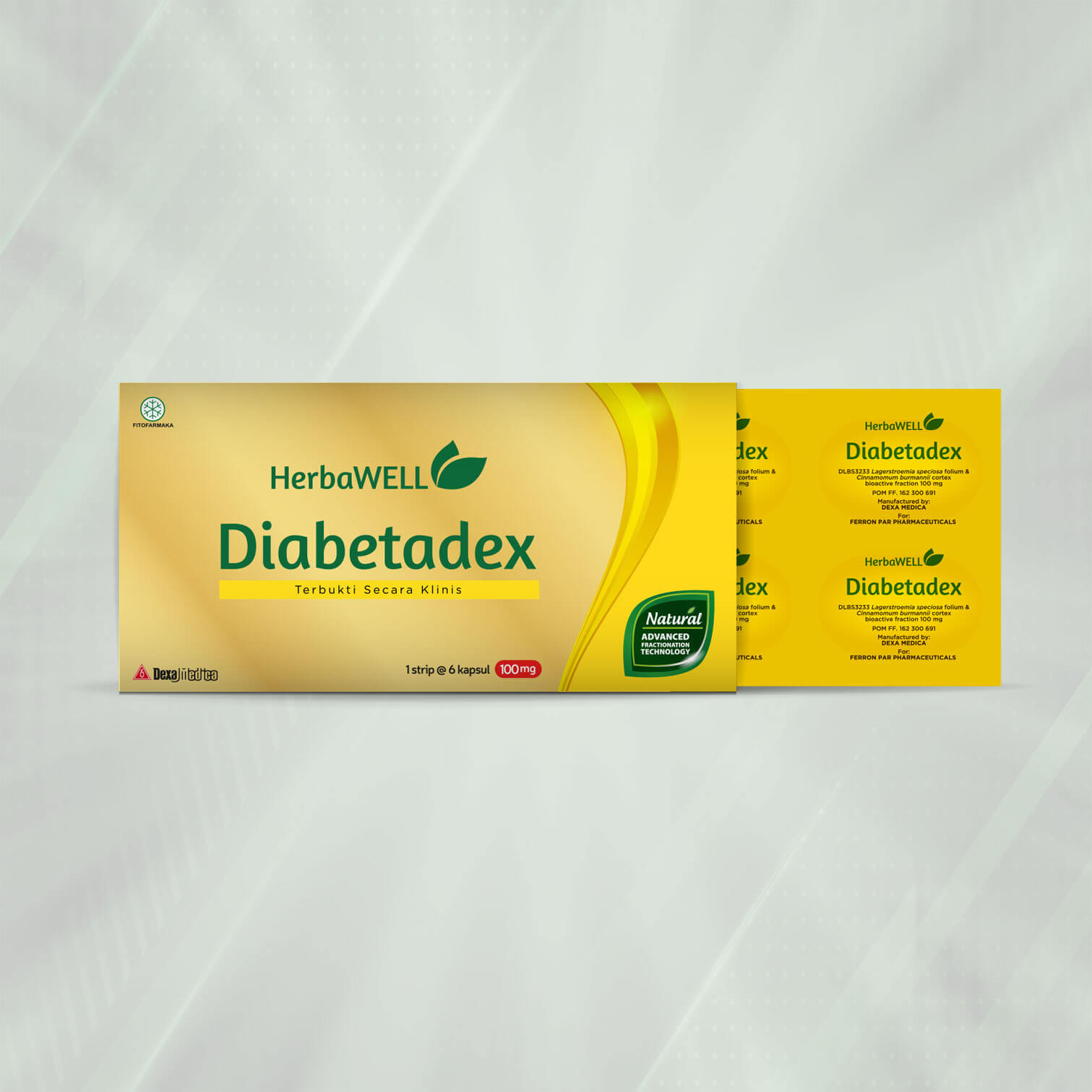

Our Portfolio

All

Pharmacy

Food & Drink

Cosmetics & Consumer Goods

Veterinary Medicine

Contact Us

we provide the high level services